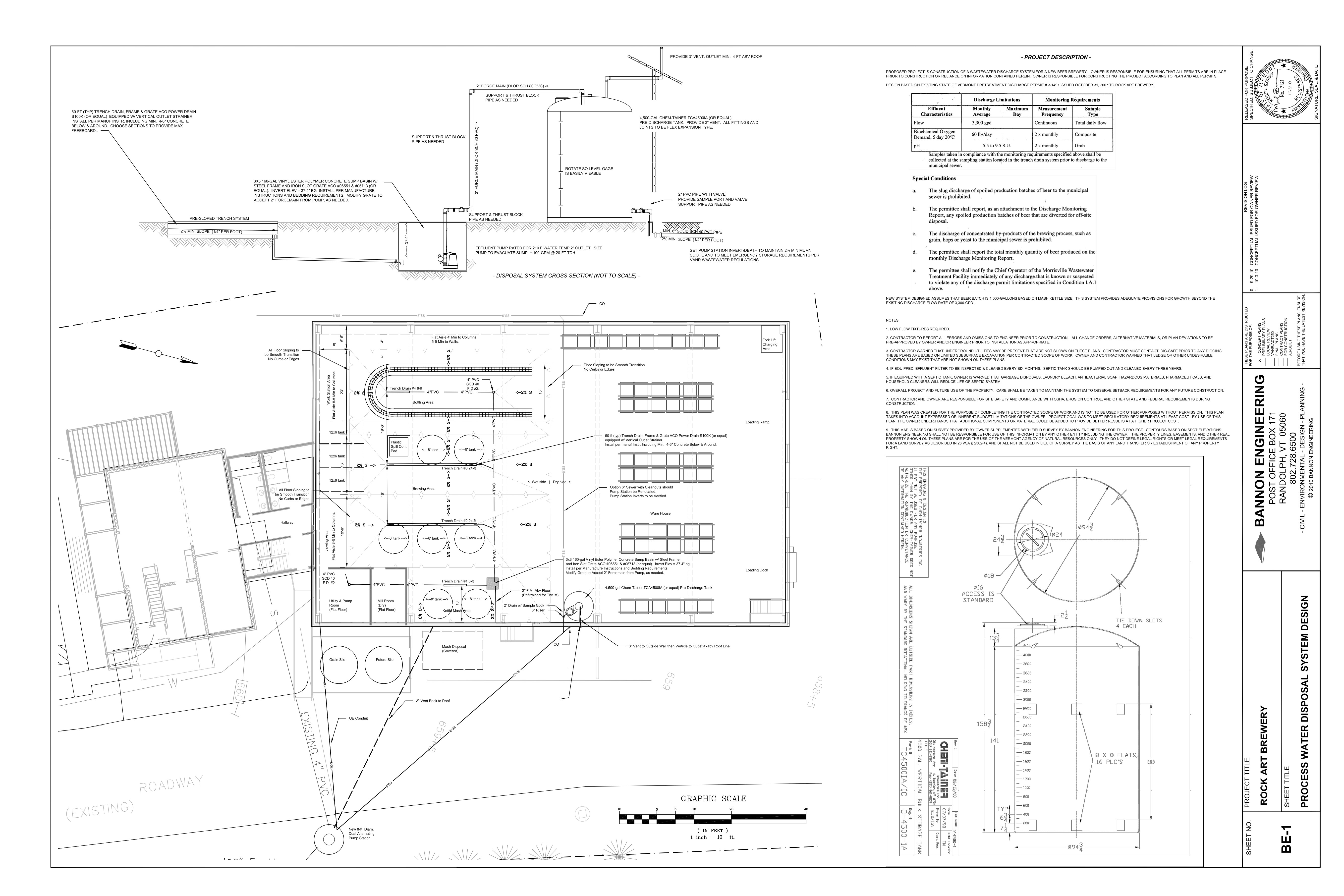

Rock Art Brewery does craft beer brewing in Morrisville, Vermont. It began production in 1997 in the Johnson, Vermont by founder Matt Nadeau. In 2009, Matt called Bannon Engineering to help him design a new state of the craft beer brewery. Rock Art is currently one of world’s top producer of craft beer and makes a world renowned Scotch Ale.

Since 2009, Bannon has assisted many craft beer brewing operations. We have trouble shooted water quality issues, designed new wells, and have addressed wastewater effluent and treatment.

Craft beer brewing is an exciting and tasty new business across the country. Craft brewing is obviously a very water and wastewater dependent activity. To craft brew the world’s finest quality craft Scotch Ale, you need the finest quality water. The worlds top brewmasters will tell you that pure water is the main ingredient. The best water to brew craft beer is typically from deep bedrock wells found in remote locations. Northern New England has many high quality aquifers. There is no coincidence that the world’s best craft beer comes from Vermont. Rock Art Brewing, Hill Farmstead, the Alchemist, Lawson, Magic Hat, Switchback Brewing, Fiddlehead, Founders are all synonymous with pure taste and it all starts with crystal clear water.

Water sources can be deep bedrock wells or municipal systems. For municipal systems, it is common to treat the incoming water to adjust pH, remove yeast killing chlorine residuals, and provide treatment to improve taste and clarity. Bannon has designed many systems to meet the top craft beer brewing Master’s strict criteria. We have sited and tested bedrock wells and can provide hydrogeological engineering studies to improve your craft brew experience.

Locations with deep bedrock wells, however, are rarely served by a municipal sewer system. The only option for beer brewing at these remote sites is to provide an on-site wastewater treatment system to handle the effluent from craft beer brewing clean-up operations. On-site systems are typically referred to as septic systems. A challenge with craft brewing on a septic systems is that beer brewing creates a high strength of wastewater and there is usually a high volume of wastewater associated with craft beer brewing operations. As the yeast works and sugars and alcohol form a high biological oxygen demand (BOD) wastewater is produced. It’s a brew! There are suspended solids that must be filtered with some passing through as wastewater. High strength detergents are used to ensure facility cleanliness.

Bannon Engineering provides expertise for craft brewing. We design cost-effective sustainable potable water systems to provide the highest purity of water to make pure craft beer brewing. Bannon also is a leading expert in designing cost-effective sustainable wastewater systems for craft brewing operations. We are looking at cutting edge ‘green’ technology which makes sense on the bottom line as well as for the environment. Contact Bannon Engineering for assistance. Bannon Engineering is a proud member of the Granite State Designers and Installers and the Lake Champlain Regional Chamber.